Overview

Vedanta Limited is a premier manufacturer of metallurgical grade alumina and other high-quality aluminium products based in India. Vedanta Limited. (VL) is renowned for its superior metallurgical grade aluminium products. At Jharsuguda, Odisha, VL runs an international standard smelter with a current capacity of 0.5 mtpa. Jharsuguda are highly developed and self-sustained manufacturing unit that has finely integrated logistics, power and human resources.

Challenges for Vedanta at Jharsuguda Aluminium Plant

Vedanta faces many challenges in their switchyard areas described below :

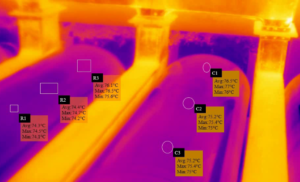

- PFIC Area has many transformers, isolators, capacitor banks, Lighting Arrestors etc. where many

connections develop hotspots. Prolonged hot spots at joints lead to breaking of the connection

eventually. - So, Vedanta requires to monitor every joints, connectors of various components daily manually using a handheld Thermal Imager and prepare a report manually.

The above procedure of manually checking each and every potential hot spot locations by going to PFIC area is not only time consuming, error prone, it is also dangerous to the person who is monitoring it with Thermal Camera. Also, like every manual operations, such manual activity is error prone, slow.

Solution Provided by Tempsens

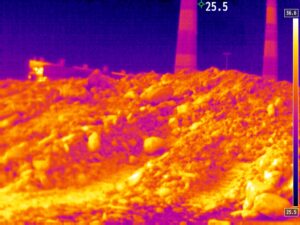

Tempsens Instruments Pvt Ltd has come up with a Solution, DCTMS ( DualCamera Thermal Monitoring System) which does automatic scanning of the designated PFIC area, identify all joints or potential hot spot location, measure temperature and prepare a report of them, highlighting any hot spot detected. HotSpot is decided as per threshold configured in the software.

DCTMS Configuration:

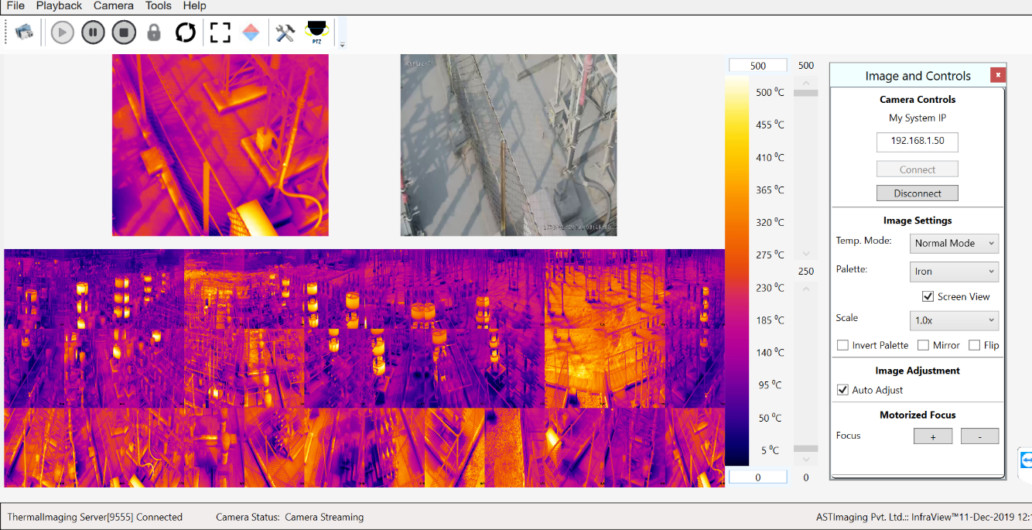

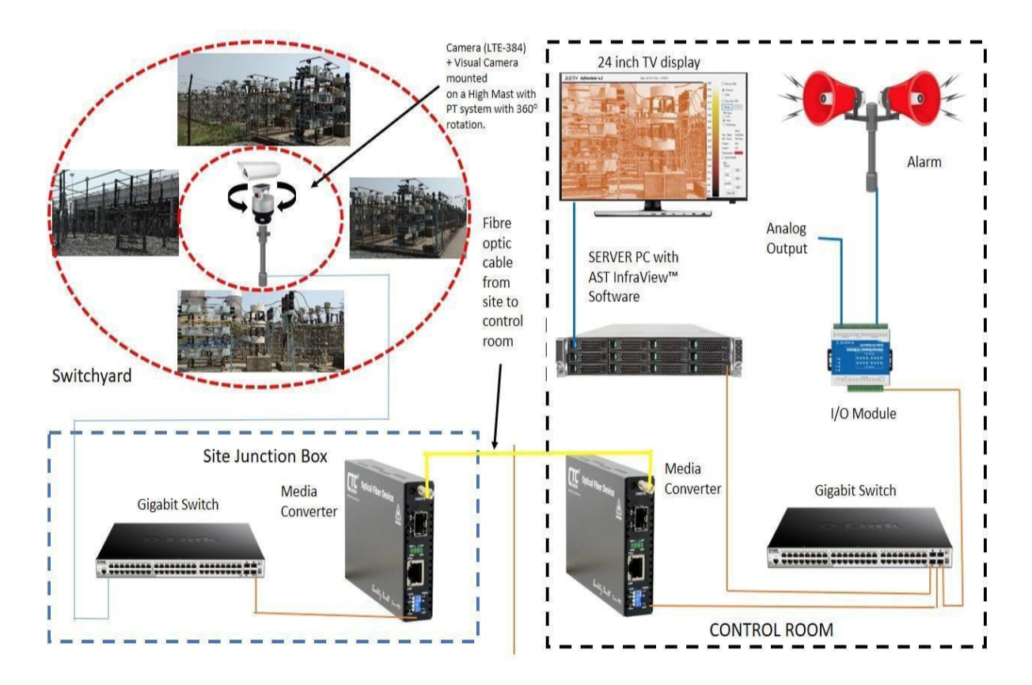

- Two AST LTE 640 cameras (Visual + Thermal) installed at site on a High mast with canopy along with

Pan and Tilt system which give 360° To and Fro motion. The Mast housed in such a way that one

camera covers Half portion of PFIC area as well as equal portion of theswitchyard area being

covered during rotation. - High end Server PC to process 2 Cameras on single Server/Machine

Tempsens DCTMS 640 requires 1 Gigabit speed to transfer high resolution images to server class PC. The image have been acquired, displayed through AST InfraViewTM Software. Our PTZ system is suitable where the image has to be transferred centralized Control Room.

DCTMS 640 allows you to continuously monitor the temperature of hotspot locations in its PFIC area remotely at its control room. It scans the PFIC area for any hot spot in every hour and displays in a large TV screen. It also generates a sound alarm when any hot spot is detected.

Result Observed

DCTMS 640 – A Substation Monitoring System, Vedanta has been able to see the below benefits

➢ No more manpower used for manual measuring temperature to detect hotspot.

➢ It has saved manpower and minimized errors

➢ Timely and automatic reports

➢ Dashboard shows last detected hotspot for easy monitoring and maintenance

➢ Trend analysis for individual hotspot has helped identifying and rectifying hot spot prone joints easy and quick.

The ability within software to draw regions of interest is a real time-saver. Thermal imaging camera, is providing an effective solution for measuring temperature to assess substation component reliability.