A conveyor belt is an important tool in many industries to carry raw material and products (like coal, clinker, etc.) from one place to another. While carrying these materials there is high chances of sudden combustion due to the presence of overheated bearing or rollers as materials like coal are highly combustible. A conveyor belt fire spreads quickly and causes high damage to equipment. It is necessary to monitor the conveyor belt in an efficient manner to reduce operation breakdown.

The Traditional way of conveyor belt monitoring by installing sensors or other temperature measuring instruments along with the entire conveyor belt is not an efficient way, as the cost of the entire system and its installation is not budget-friendly, also the accuracy of temperature measurement is a key factor.

Solution

Thermal cameras can detect the sudden rise in temperature to prevent fire, it can detect the hidden trouble of aging and fracture in the conveyor belt, with this it can also be used to detect hot material on the conveyor belt for example while transporting cooled clinker in cement industries some clinker particles get remained un-cooled which can affect the quality of cement and can also damage the belt.

In industries like the glass industry, steel industry maintaining the minimum temperature of products is important, here thermal cameras can play a significant role in monitoring temperature and video streaming by the camera will also provide the details of the uniformity of the product.

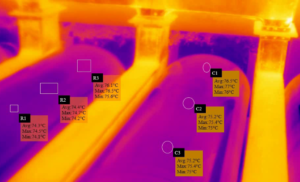

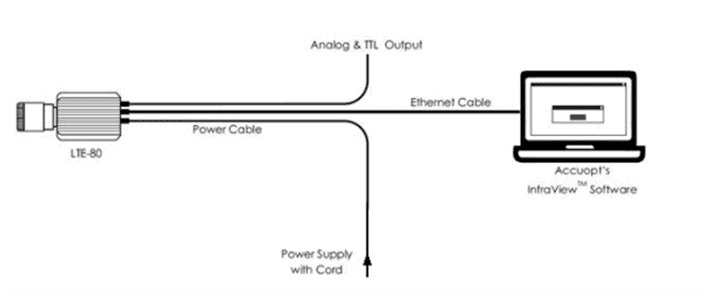

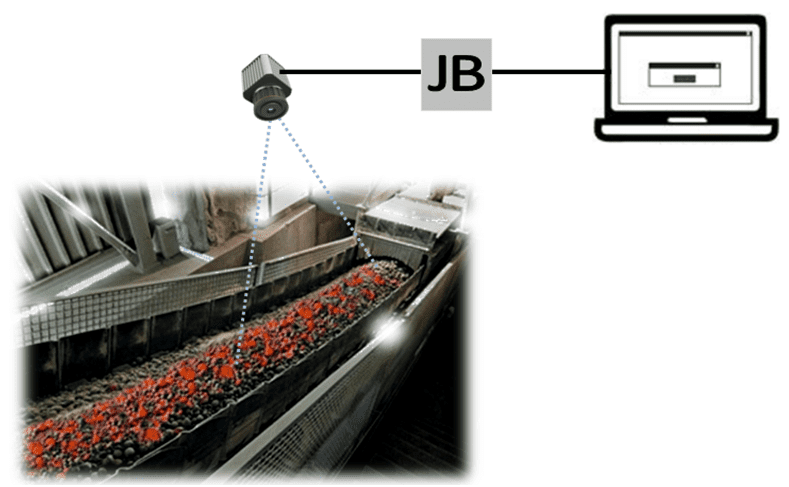

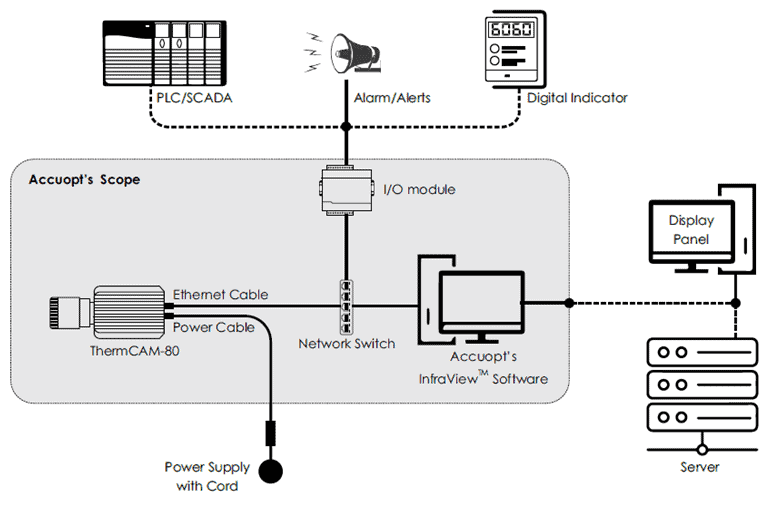

Accuopt’s Conveyor Belt Monitoring system is a reliable system, which increases plant, personnel, and equipment safety. The System uses Accuopt make ThermCAM-80 thermal cameras, which provide continuous monitoring. ThermCAM-80 is an LWIR, 80×80 pixel resolution thermal camera which measures temperature with precision. The lens used in the camera covers the maximum area of the conveyor belt. ThermCAM-80 will capture thermal images/videos and transfer them to the InfraView™ software installed in the PC at the control room. Region of Interest ( ROIs) can be drawn to monitor the temperature of a particular region.

Alarms or alert signals can be generated on detecting hot spots. ThermCAM-80 can be used as a standalone system, which means we can get direct Analog & TTL output from the camera, without connecting to software.

The system is designed with specific features to withstand in harsh environmental conditions.

Installation

ThermCAM-80 thermal cameras will be installed alternatively along with the entire conveyor belt. ThermCAM-80 has a wider field of view as compared to other temperature measuring instruments like pyrometers, so fewer numbers of cameras will be required to cover the entire belt.

Advantages of System

- Early fire detection

- Improve equipment and personnel safety

- Alarm generation or alert feature

- Reduced the risk of damage of conveyor belt by early detection of abnormal temperature.

- Automatic monitoring device; no operator interaction required i.e. storage of images, measured temperature and process related data.

- Easy interface and flexible according to operation needs