In any plastic industry, the manufacturing process comprises of different process like injection molding, thermoforming etc. During each of these stages, temperature plays an important role in the quality of final product. Maintaining the temperature and it’s measurement assures the quality of a product.

Traditionally used contact type temperature sensors have a very short life span, So non-contact temperature measuring instruments like pyrometers or thermal cameras can be used for this application

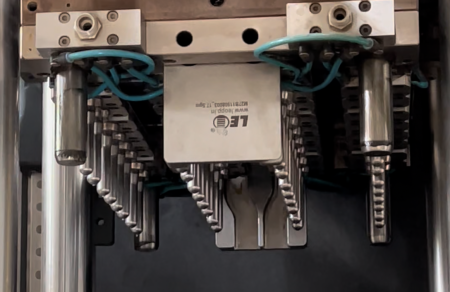

Injection Molding

In the injection molding process, the plastic granules are heated to the liquid stage

and then injected into the mold. After injecting into the mold it is allowed to

cool down.

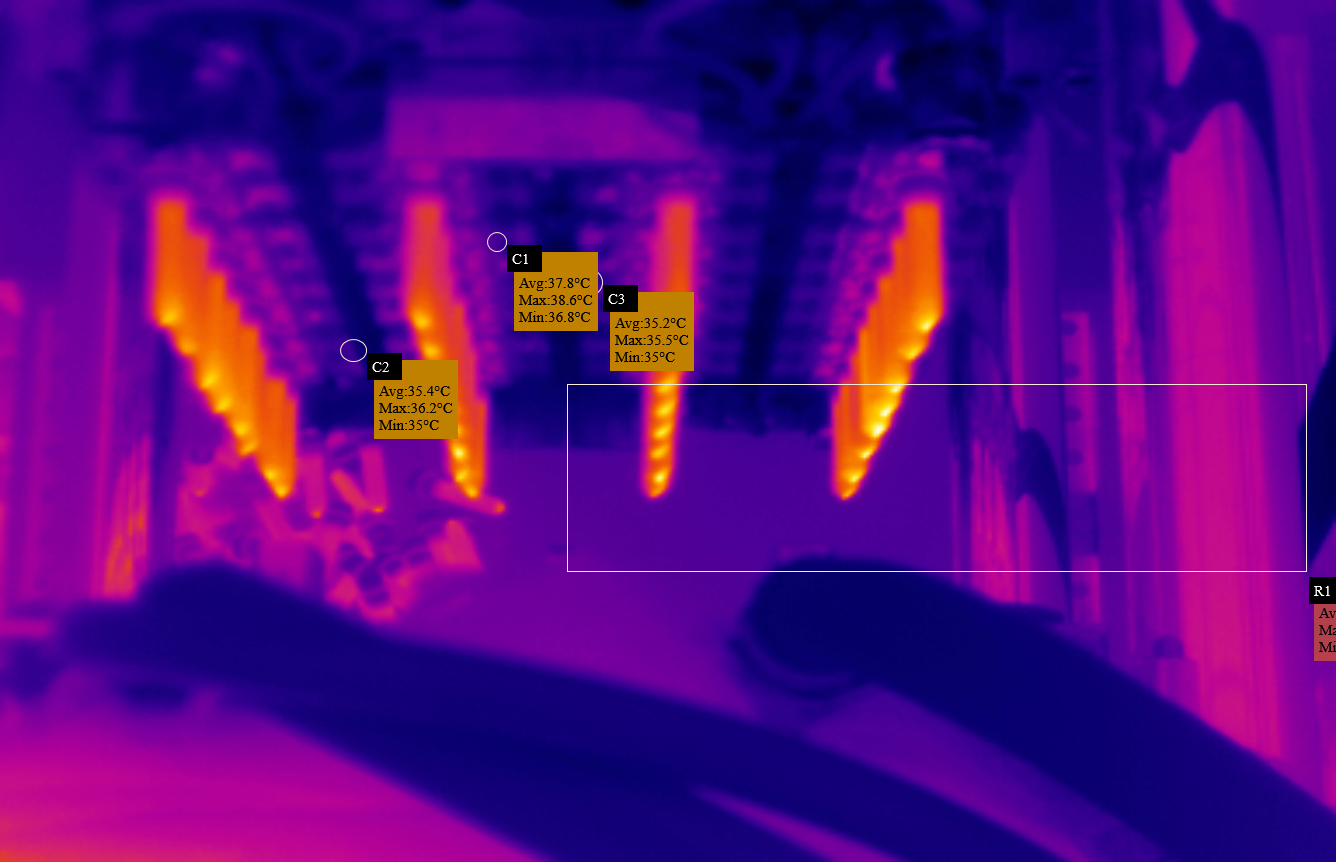

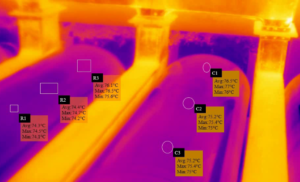

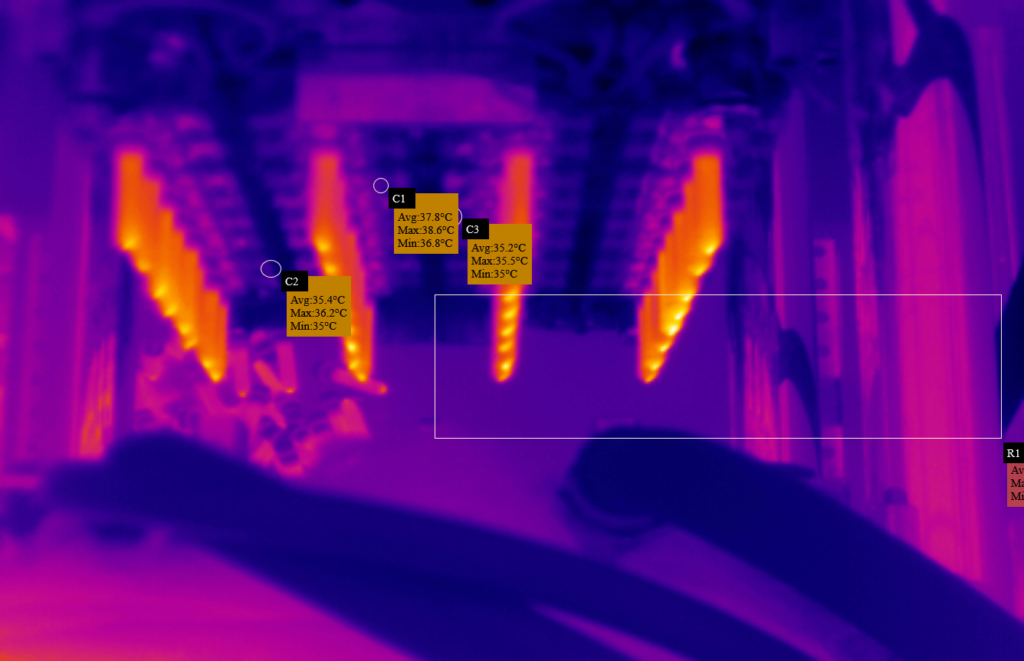

To avoid twisting and deforming during the process, our fixed thermal imager ThermCAM-384 can be used to monitor the process. Temperature overshoot and undershoot (hot spots and cold spots) can be determined by temperature monitoring of shaped parts while taking off the mold, with this mold temperature can also be easily measured and timely mold temperature can be adjusted.

Advantages

- On-time temperature adjustment of molds.

- Improves the quality of finished products.

- Reduce the cycle time.

- Reduce the number of discarded goods and reduce the cost of rejection.

- Generate alarms on detection of hot spots, which helps in indicating predictive maintenance which reduces high maintenance costs.

Key Features

- Provide continuous thermal video in InfraView™ Software.

- Different types of ROI (Region Of Interest) can be drawn for localized temperature monitoring.

- Histogram and trend chart of ROI can be generated for data analysis.

- Includes 9 different color palates which can be selectable as per the user demand

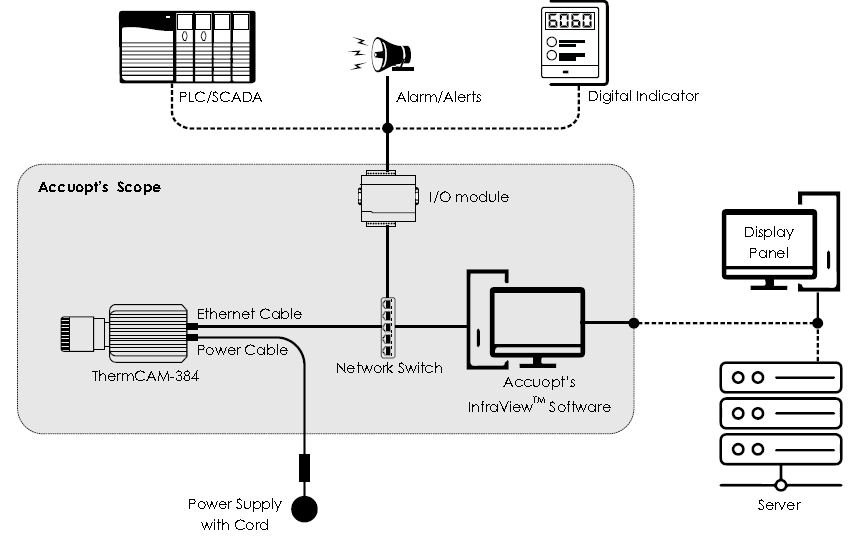

Thermal Camera Connections

- ThermCAM-384 provides Ethernet output. The camera has two connectors at the back side one is power connector and another one is RJ45 Ethernet connector.

- The camera get connected to PC installed with InfraView™ software which allows to stream thermal videos/images.

- This camera output can also be taken over PLC/SCADA, digital indicators or hooters/ alarms etc. through I/O module via a network switch.

- This Accuopt’s I/O module provide 2 relay outputs and 4 analog output of 4-20mA.