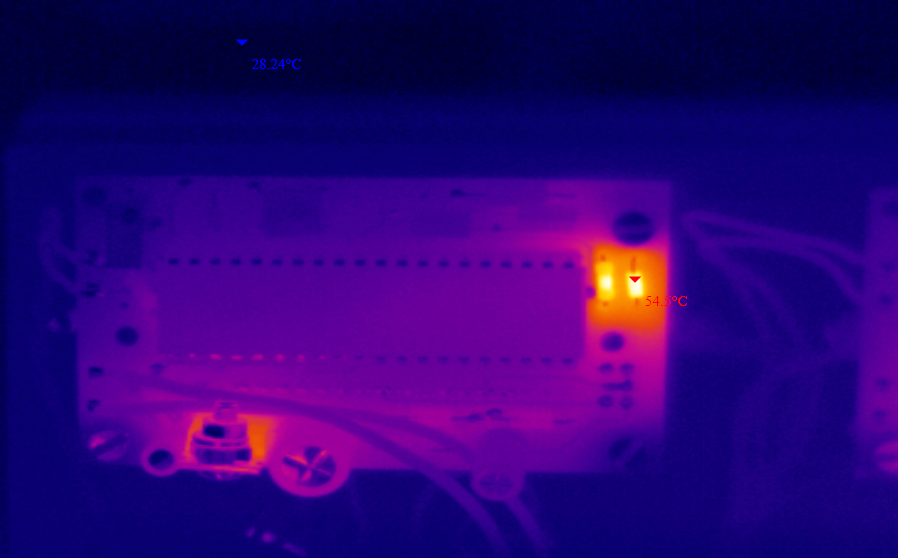

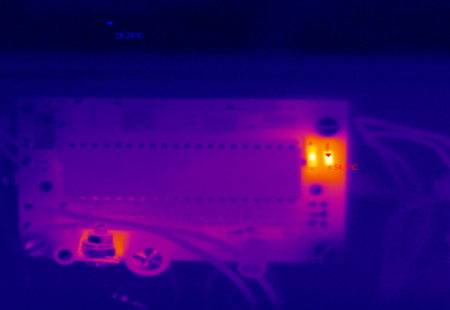

Production and designing of printed circuit boards (PCB) need high precision and it is quite difficult to track down the defects, malfunctioning, or failures in the elements. On supplying voltage or when current passes through the circuit, the PCB starts heating. Thermal cameras can be used to spot PCB faults. Any element consuming high current or malfunctioning will generate heat and the thermal camera will easily detect the temperature difference across their field of view. Thermal imaging boosts the PCB design process and shortens the development time. By using thermal mapping designers can determine the heat allocation and add cooling components accordingly.

Handled (portable) or online (stationary) thermal cameras, both have significance in the thermography of PCBs. When the temperature measurement of a single PCB is required, there portable thermal cameras can be used, and when thermography of multiple PCBs (like at exit of component assembly line) is required simultaneously like during the manufacturing process of PCB in bulk as it has a wider viewing angle.

Accuopt’s wide range of thermal cameras completes the purpose and fits the customer’s needs. Its, widely used thermal camera ThermCAM-640 is an LWIR camera and has an Uncooled FPA detector with 640 x 512 pixel resolutions and works over the spectral range of 8-14μm. ThermCAM-640 comes with 13mm standard lens, other lens options are available, widely used lens for PCB inspection is 20.5mm macro lens. The macro lens helps to get the precise temperature of small components.

Advantages

- Quick fault analysis.

- Reduced production time by quick sorting of defective PCBs.

- Reduce the cycle time.

- Generate alarms on detection of hot spots.

Key Features

- Provide continuous thermal video in

- InfraView™ Software.

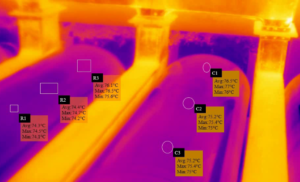

- Different types of ROI (Region Of Interest) can.

- be drawn for localized temperature monitoring.

- Histogram and trend chart of ROI can be generated for data analysis.

- Includes 9 different color palates which can be selectable as per the user demand.

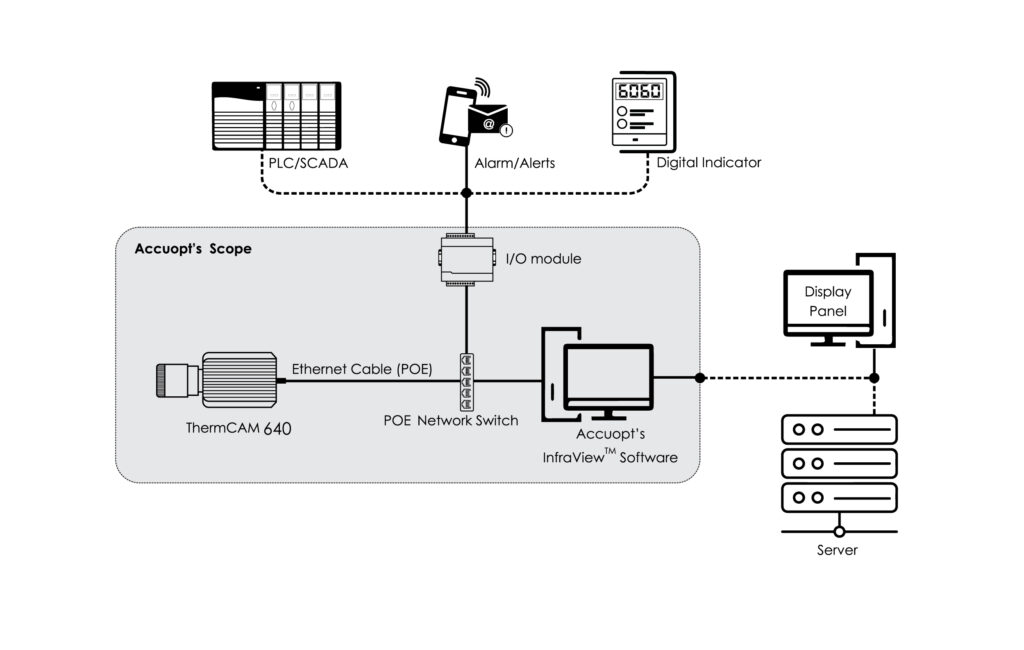

Thermal Camera Connections

- ThermCAM-384 provides Ethernet output. The camera has two connectors at the back side one is power connector and another one is RJ45 Ethernet connector.

- The camera get connected to PC installed with InfraView™ software which allows to stream thermal videos/images.

- This camera output can also be taken over PLC/SCADA, digital indicators or hooters/ alarms etc. through I/O module via a network switch.

- This Accuopt’s I/O module provide 2 relay outputs and 4 analog output of 4-20mA.