Just like metallurgical industries, textile and paper industries also avails the benefits of thermal imaging cameras in various applications such as electrical systems, motors and mechanical equipment, liquid levels in boilers and other vessels, heaters and dryers, steam traps, and process lines for blockage.

Dryers

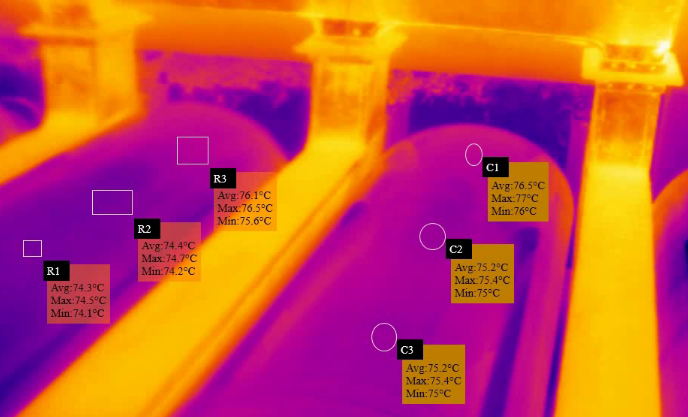

In the process of drying, the moisture content from paper/fabrics is removed by evaporating the liquid portion. Industries use different techniques for the drying process like heating, blowing dry air, centrifuging, vacuum process, or exposure to sunlight. The most commonly used method is heating. The de-watered fabric or paper sheets are fed to dryers, in which the heaters are installed. The temperature of feed fabric lies between 20°C to 30°C and as the water starts evaporating from the fabric, the temperature of the fabric also starts increasing.

Overheating of fabric can burn the yarn and will affect the texture and quality. Underheating of fabric will cause swelling of yarn due to the presence of moisture, so proper heating of fabric and maintaining the temperature is important.

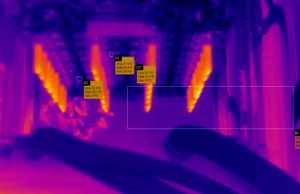

A thermal camera such as Accuopt’s ThermCAM 384 can be used to inspect the temperature. When the fabric is fed, the thermal camera will provide real-time infrared video of wet fabric/paper and roller. The initial temperature of the fabric will be recorded between 20°C to 30°C and a threshold temperature can be set at ~80°C, over which if the temperature of the fabric rises it will generate an alarm and heaters can be turned off. Along with controlling the surface humidity, a thermal camera can also help in investigating, observing, and maintaining other properties of fabric.

ThermCAM-384 thermal camera is a noncontact temperature measuring instrument that can measure the temperature from -20°C to 120°/100°C to 1000°C (other temperature ranges are also available). It can detect the spectral range of 8-14 μm and has the accuracy of ±2% of reading in °C or °K.

Advantages

- Prevents the fabric from burning out

- On-time temperature adjustment of heaters based on observation of temperature data.

- Improves the quality of finished products.

- Operators can detect non-uniformities and can make immediate corrective adjustments.

- Generate alarms on detection of hot spots, which helps in predictive maintenance and reduces high rejection costs or reprocessing.

Key Features

- Provide continuous thermal video in InfraView™ Software.

- Different types of ROI (Region Of Interest) can be drawn for localized temperature monitoring.

- Histogram and trend chart of ROI can be generated for data analysis.

- Includes 9 different color palates which can be selectable as per the user demand

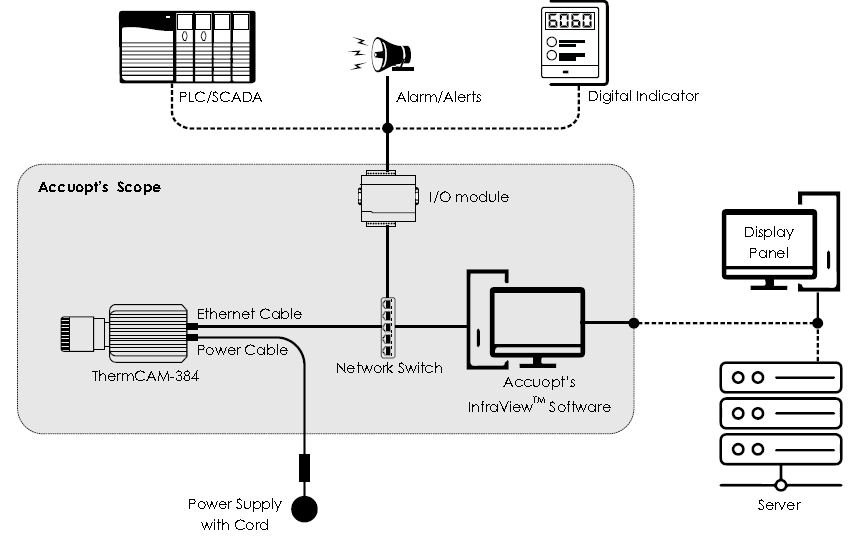

Thermal Camera Connections

- ThermCAM-384 provides Ethernet output. The camera has two connectors at the back side one is power connector and another one is RJ45 Ethernet connector.

- The camera get connected to PC installed with InfraView™ software which allows to stream thermal videos/images.

- This camera output can also be taken over PLC/SCADA, digital indicators or hooters/ alarms etc. through I/O module via a network switch.

- This Accuopt’s I/O module provide 2 relay outputs and 4 analog output of 4-20mA.