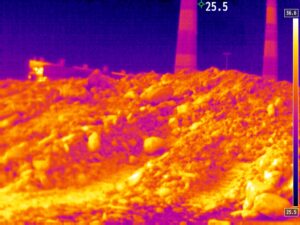

During the die-casting process, the molten metal is forced into the mould cavity with high pressure. Surface monitoring during this process is crucial, as to measure the uniformity of the dies after and before casting. As this aluminium casting is an automatic process using a robotic system. If the dies are too hot, the robot will not able to withdraw the casted part, as aluminium will stick to the dies, and also it will be indicating the cooling process of the dies is not performing well.

If the dies are too cold, aluminium will not be cast properly as it will become solid before it reaches the end of the cavity and again, it also indicates some issue with the cooling parameter.

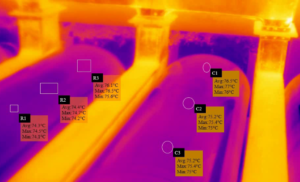

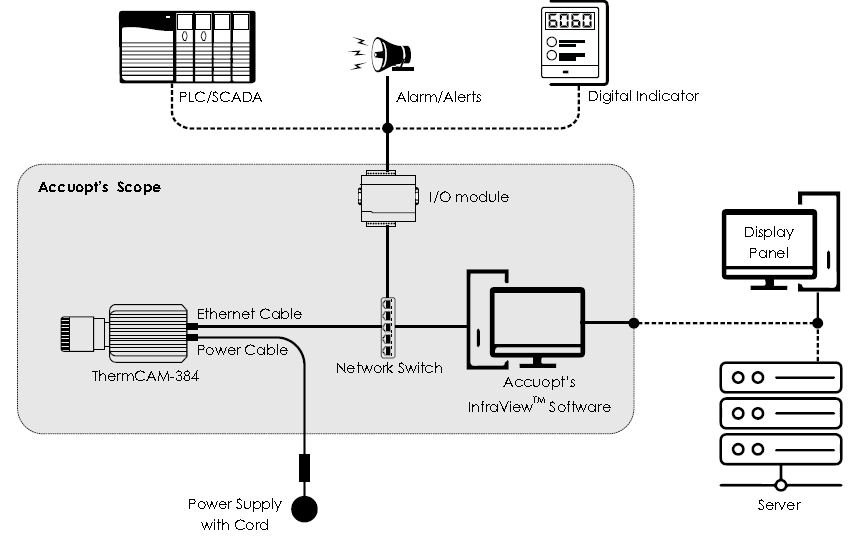

ThermCAM series thermal imaging cameras provide real-time video/image with temperature monitoring. Its high-performance IR sensor captures and visualizes the thermal map of the die surface. A threshold temperature can be set on individual ROI’s, over which if the temperature of the die rises an alarm will be generated. The thermal camera can also be integrated with PLC, SCADA, relay, hooter, or any other

triggering instrument by using an I/O module which can provide analogue and digital output (4-20mA).

Advantages

- Realtime temperature adjustment of moulds.

- Improves the quality of finished products.

- Reduce the cycle time.

- Reduce the number of discarded goods and reduce the cost of rejection.

- Generate alarms on detection of hot spots, which helps in indicating predictive maintenance which reduces high maintenance costs.

Key Features

- Provide continuous thermal video in InfraView™ Software.

- Different types of ROI (Region of Interest) can be drawn for localized temperature monitoring.

- Histogram and trend chart of ROI can be generated for data analysis.

- Includes 9 different colour palates which can be selectable as per the user demand

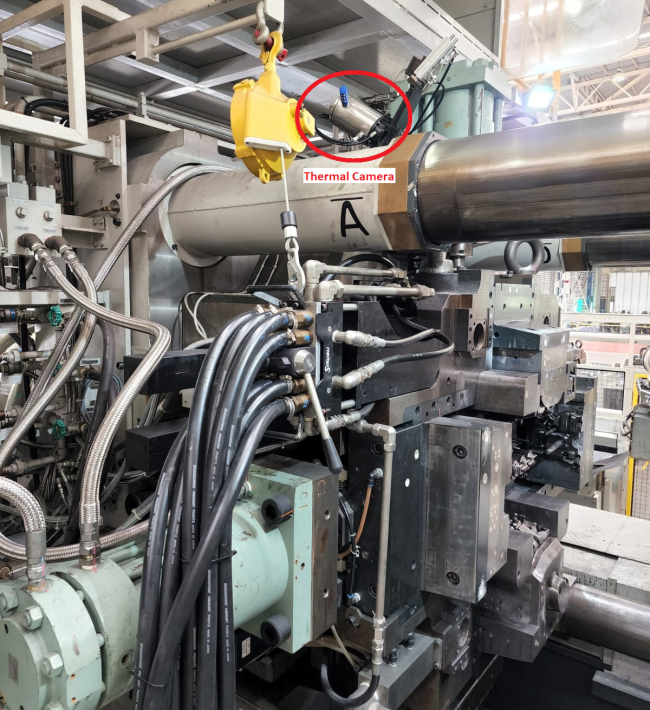

Thermal Camera connections

- Our ThermCAM cameras provides Ethernet output. The camera has two

connectors on the back side one is a power connector and another one is an RJ45 Ethernet connector. - The camera gets connected to a PC installed with InfraView™ software which allows streaming thermal videos/images.

- This camera output can also be taken over PLC/SCADA, digital indicators or

hooters/ alarms, etc. through the I/O module via a network switch. - Accuopt’s I/O module provides 2 relay outputs and 4 analogue outputs of 4-

20mA.