High Resolution LWIR Ultra

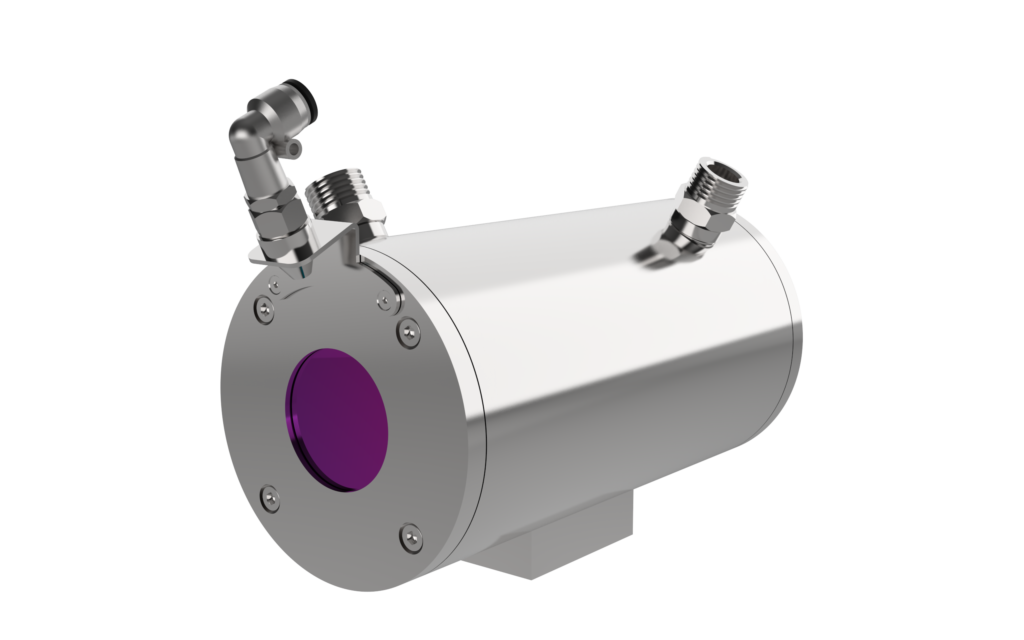

Compact Infrared Camera for Glass Industry Temperature Measurement Solutions.

ThermCAM-384G is a versatile thermal camera with a spectral range of 7.9μm, which can be used for a wide range of temperature measurement for glass industry applications

150°C to 1500°C

384 x 288 pixels

Upto 30Hz

Ethernet

ThermCAM-384G caters the best balance between image clarity and data transfer rate with its optimum resolution of 384 x 288 pixels. It provides ultimate inspection tools and unprecedented easy-to use designs to fit your needs. Whether in quality control, process monitoring or process automation – the infrared camera ThermCAM-384G measures temperatures without contact exactly and reliably.

| Temperature Range | 150°C to 1500°C |

| Optional Resolution | 384 x 288 pixels |

| Detector | Uncooled FPA Detector |

| Frequency | Up-to 30Hz |

| Accuracy | ±2°C or ±2% of reading in °C or °K |

| Spectral Range | 7.9 μm |

| Sensitivity / NETD | <50mK@f1.0, 30Hz 300 K |

| Pixel Pitch | 17 μm |

| Digital | 100MBit/s |

| Connection | Power Connector, RJ-45 Ethernet Connector |

| Video Format for Saving | MPEG-4 |

| Image Format for Saving | BMP/JPEG |

| Power Supply | 12 – 28 V DC |

| Power Consumption | <4 Watt |

| Ambient Temperature | 0°C – 50°C |

| Storage Temperature | -40°C – 70°C |

| Relative Humidity | ≤95% non-condensing |

| Shock Resilience | 25G |

| Vibration Resilience | 2G |

| Weight | ~550g (with 13mm lens) |

| Protection Class | IP65 |

| EMC | CE |

| Size | 60 x 70 x 96 mm (with 13mm lens) |

| Mounting | UNC 1/4”-20, UNC 3/8″-16 Standard Mount |

| Analog Output | 4 Channel Analog Current Output (4 – 20mA) |

| Digital Input | 2 Isolated Inputs |

| Digital Output | 2 Relay Outputs |

| Power Supply | 5 V DC |

| Focal Length | 13mm (Standard Lens) |

| Field of view | 28.1°(H) x 21.3°(V) |

| Focus | Fixed |

| Note : Other lenses also available on request FL =15mm (24.6°x18.5°), FL = 19mm(19.5° x 14.7°), FL= 50mm(7.5° x 5.6°), Fl= 75mm(4.9° x 3.7°) & FL= 100mm(3.7° x 2.8°) | |

Infraview™

ThermCAM-384G has a thermal image processing software InfraViewTM at the core of a thermal imaging system which is customizable with Client – Server Architecture for catering to multiple clients at the same time. The modular windows software InfraViewTM can be configured / customized to cater to application / solution requirements.

Accuopt’s InfraViewTM software allows you to control the camera record, view, manipulate and store the captured video / image as well as measured temperature data. This real time software allows simple and fast parameterization for documentation of the temperature data for optimizing process control.

Special Features

The I/O module consist of digital input/digital output(relay output) and analog 4 –20mA, which can be mounted on Din-rail. It provides analog and relay outputs with respect to temperature. These outputs can be customized for temperature indication, alarm generation or error reporting.