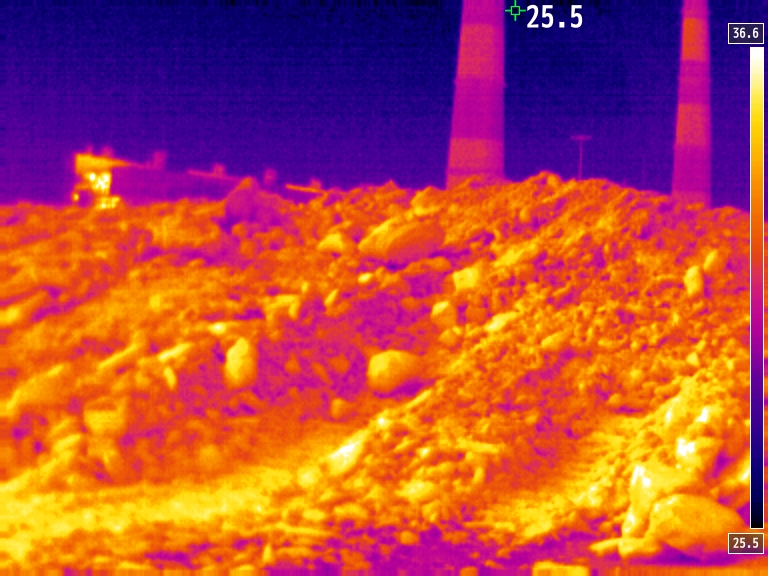

Many industries are using coal as a primary fuel for igniting furnaces, boilers, or any other heating equipment. These industries store coal in the yard in bulk as per their daily consumptions. There is a high risk in storing the coal in large quantities, as coal is a highly volatile substance and easily gets self-ignited due to a rise in temperature. As ignition at one spot can result in a spontaneous fire in the whole field.

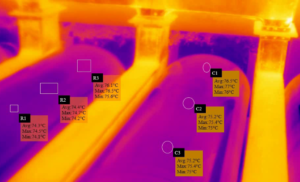

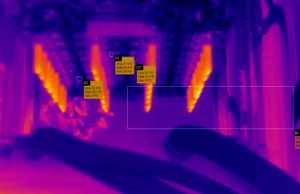

As always, prevention is better than cure. Thermal cameras (ThermCAM-384/640) are the most availing solution for early fire detection. The thermal camera will provide real-time thermal video/image and the temperature data of the surface of coal piles. As the coal gets ignited a rise in temperature will be reflected on the surface of the coal pile and the thermal camera will easily detect the hot-spot and will generate an indicating alarm to alert the personnel. This complete hardware system is integrated with the software. The software streams the thermal and visual video/images, it also has PTZ controls and many other software features.

ThermCAM-384 thermal camera is a noncontact temperature measuring instrument that can measure the temperature from -20°C to 120°/100°C to 1000°C (other temperature ranges are also available). It can detect the spectral range of 8-14 μm and has the accuracy of ±2% of reading in °C or °K.

Advantages

- Early fire detection

- Improve equipment and personnel safety

- Alarm generation on the detection of hot-spot

- Automatic monitoring device; no operator

required i.e. stores the images, measured temperature, and process

related data - Easy interface and flexible according to

operation needs

Key Features

- Provide continuous thermal video in InfraView™ Software

- Different types of ROI (Region of Interest) can be drawn for

localized temperature monitoring - Histogram and trend chart of ROI can be generated for data analysis

- Includes 9 different color palates which can be selectable as per

the user demand

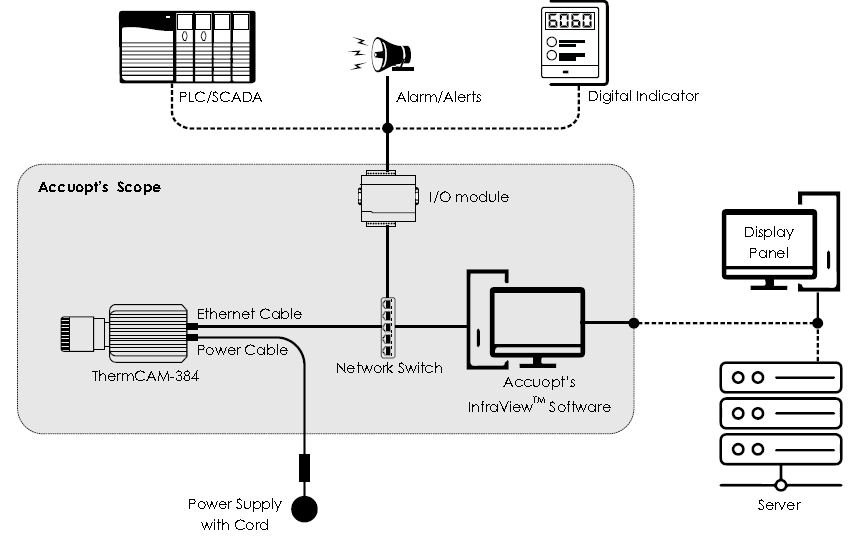

Thermal Camera Connections

- ThermCAM-384 provides Ethernet output. The camera has two connectors on the back side one is a power connector and another one is an RJ45 Ethernet connector.

- The camera gets connected to a PC installed with InfraView™ software which allows streaming thermal videos/images.

- This camera output can also be taken over PLC/SCADA, digital indicators or hooters/ alarms, etc. through the I/O module via a network switch.

- This Accuopt’s I/O module provides 2 relay outputs and 4 analog output of 4-20mA.