Kilns are refractory-lined rotating drums that are slightly inclined at a horizontal axis. In this process, a mixture of raw materials like Iron (Fe), limestones, dolomite, and olivine is formed and bentonite is used as the binder. This mixture is fed into the pellet kiln in which the mixture is heated at high temperature to form iron pellets. Iron pellets are hard spheres formed through the heating treatment of the pelletizing concentrate. These pellets are further used as raw materials for blast furnace.

These refractory-lined vessels have limited lives, as the lining starts degrading over time and the outer metal wall which may lead to complete depletion and greater chances of accidents. The risk of breakdown of these refractories will always be present in metallurgical plants, with equipment damage and loss of production as the costly consequence.

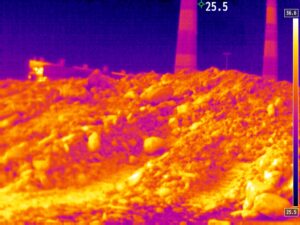

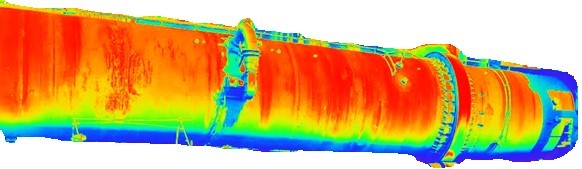

The re-lining & maintenance of these refractories has a significant contribution to the steel production cost. Tracking the temperature pattern of the external surface of kilns allows in assessing the distribution and extent of depletion. These details can be can be used to provide a re-lining scheme for the damaged area and increases the utilization of kilns by avoiding excessive lining damage and break-outs.

Solution

Kiln Refractory Healthiness Monitoring System from AccuOpt provides a precise and reliable measurement solution to enhance plant safety and helps in organizing maintenance schedules in metallurgical plants across the world. In this solution AccuOpt’s ThermCAM-384 thermal camera will be installed at a position from where it will have a clear view of the Kiln.

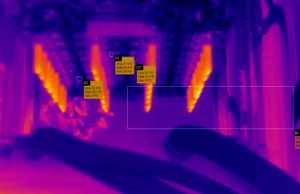

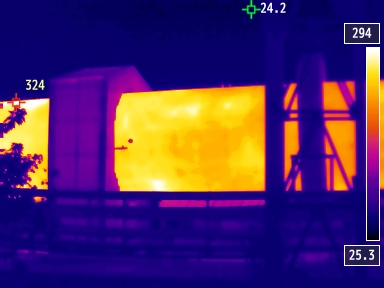

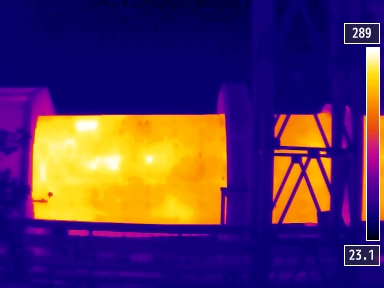

The lens used in the camera has such FOV so that it can cover the complete profile of the Kiln. The camera system captures real time thermal video/images of the Kiln surface. An increase in temperature at the kiln outer shell gives a clear indication of refractory damage, alarming to set a schedule for refractory relining.

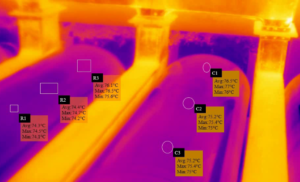

To get the more precise temperature of a particular region, configurable ROIs can be defined for analysis. The captured thermal images and temperature data can be exported and stored for analysis and quality control.

ThermCAM-384 Thermal Imager is integrated with InfraView™ software, which allows collecting the raw data from the camera. Through software, one can record, view, analyse and store the captured video/image as well as measured temperature data. InfraView™ is a Windows based software, which is customizable as per the user requirements and application. It provides quick & easy framework for the documentation of the temperature data collected through the thermal camera, which helps in optimizing the process control.

Advantages

- Automatic and non-contact temperature measurement system, which increases personnel safety

- Improve kiln safety

- Increases refractory life span

- Allows timely relining of refractory

- Generate alarms on detection of hot spots, which helps in predictive maintenance and reduces high rejection costs or reprocessing.

Key Features

- Provide continuous thermal video in InfraView™ Software.

- Different types of ROI (Region Of Interest) can be drawn for localized temperature monitoring.

- Histogram and trend chart of ROI can be generated for data analysis.

- Includes 9 different colour palates which can be selectable as per the user demand

Thermal Camera connections

- ThermCAM-384 provides Ethernet output. The camera has two connectors on the back side one is a power connector and another one is an RJ45 Ethernet connector.

- The camera gets connected to a PC installed with InfraView™ software which allows streaming thermal videos/images.

- This camera output can also be taken over PLC/SCADA, digital indicators or hooters/ alarms, etc. through the I/O module via a network switch.

- This Accuopt’s I/O module provides 2 relay outputs and 4 analog output of 4-20mA.