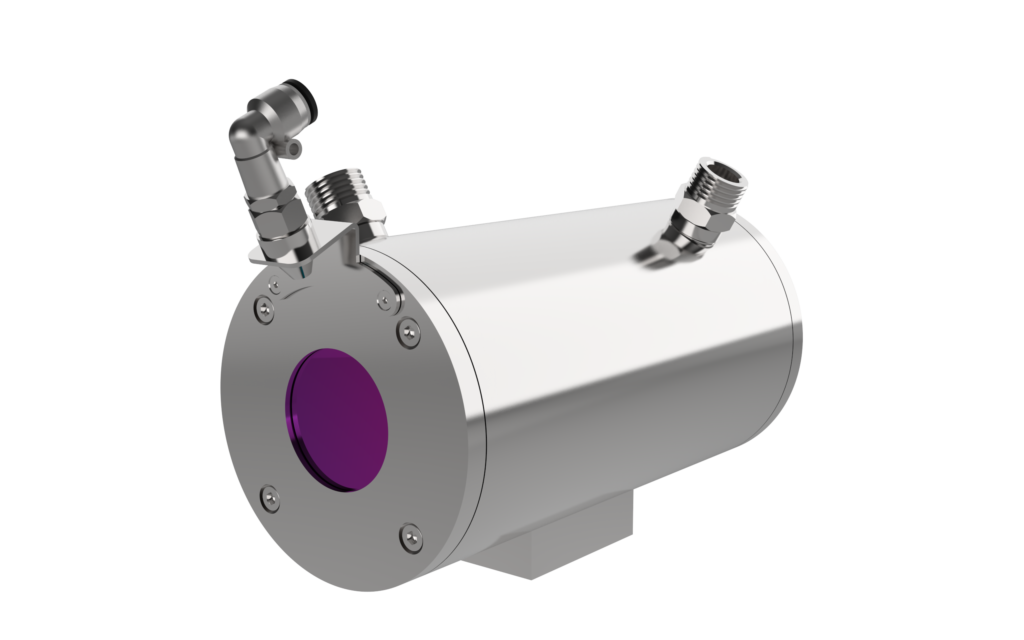

ThermCAM-80 Thermal imaging camera offers a broad range of applications across several different industries.

-20 to 120°C | 100 to 1000°C

(Switchable)

80 x 80 pixels

Upto 25Hz

Ethernet, 4-20mA & Digital output

Currently industries are using spot temperature pyrometers to measure the temperature of critical points. ThermCAM-80 can replace such pyrometers with better area coverage and will also give individual pixel temperatures. Also, ThermCAM-80 has the advantage of showing the thermal image which makes it more suitable for continuous monitoring of critical assets. High resolution, like 640×480 pixels, is not always needed in industrial applications. Sometimes we just need to identify faults. So ThermCAM-80, 80×80 pixels, is the most economical solution. ThermCAM-80 Thermal imaging camera offers a broad range of applications across several different industries.

Most of industries or plants need to run continuously 24 hours a day, 365 days a year so in order produce faster, better and more efficient result at lower cost thermal imaging cameras are best option. Thermal camera are the most economic option for identifying failures before they cause any catastrophe.

| Temperature Range | -20°C to 120°C | 100°C to 1000°C (Switchable) |

| Optical Resolution | 80 x 80 pixels |

| Detector | Uncooled FPA Detector |

| Frequency | up-to 25Hz |

| Emissitivity | 0.01 – 1.0 adjustable |

| Accuracy | ±2% of reading in °C or °K (Ambient temp @25°C) |

| Spectral Range | 8 to 14 μm |

| Sensitivity / NETD | <100mK@f1.0, 50Hz 300 K |

| Pixel Pitch | 34 μm |

| Video | 100MBit/s Ethernet |

| Connection | Power Connector, RJ-45 Ethernet Connector |

| Output | 4 – 20mA | 1 TTL output |

| Video Format for Saving | MPEG-4 |

| Image Format for Saving | BMP/JPEG |

| Power Supply | 12 to 28 V DC |

| Power Consumption | <4 Watt |

| Ambient Temperature | 0°C – 50°C |

| Storage Temperature | -40°C – 70°C |

| Relative Humidity | <95% non-condensing |

| Shock Resilience | 25g |

| Vibration Resilience | 2g |

| Weight | ~550g (with 5.56mm lens) |

| Protection Class | ~IP65 |

| Size | ~60 x 60 95mm (with 5.56mm lens) |

| Mounting | UNC 1/4”-20, UNC 3/8”-16 Standard Mount |

| Analog Output | 4 Channel Analog Current Output (4 – 20mA) |

| Digital Input | 2 Isolated Inputs |

| Digital Output | 2 Relay Outputs |

| Power Supply | 5 V DC |

| Focal Length | 5.56mm (Standard Lens) |

| Field of view | 28°(H) x 28°(V) |

| Focus | Manual Focus |

Infraview™

ThermCAM-80 has a thermal image processing software InfraViewTM at the core of a thermal imaging system which is customizable

with Client – Server Architecture for catering to multiple clients at the same time. The modular windows software InfraViewTM

can be configured / customized to cater to application / solution requirements.

Accuopt’s InfraViewTM software allows you to control the camera record, view, manipulate and store the captured video /

image as well as measured temperature data. This real time software allows simple and fast parameterization for

documentation of the temperature data for optimizing process control.

Special Features

The I/O module consist of digital input/digital output (relay output) and analog 4-20mA, which can be mounted on Din-rail. It provides analog and relay outputs with respect to temperature. These outputs can be customized for temperature indication, alarm generation or error reporting.